Overview of SAFF

The SAFF – Surface Active Foam Fractionation process utilizes the physio-chemical properties of PFAS compounds to attach to fine air bubbles as a result of its hydrophobic and hydrophilic properties. When bubbles are introduced and allowed to rise in a narrow column of PFAS-contaminated water, the bubbles become exceptionally effective in collecting PFAS compounds that are loosely bound to the water molecules. Once at the surface, PFAS can easily be removed by separation.

Treated (aerated) water can then be released to the recipient (if concentrations of contaminants are below quality criteria(s)) or go through further treatment with using other remediation technologies suitable for low contaminated water e.g. phytoremediation and anion exchange filters (AEX).

The collected PFAS concentrate is passed on to further fractionation steps to become a high concentration liquid of relatively small volume suitable for destruction via permanent destruction techniques such as high temperature thermal combustion, Super Critical Water Oxidation (SCWO) or Electrochemical Oxidation (EO).

The system has significant advantages compared to all other technologies on the market as the process is very robust. SAFF works without reduced effect, regardless if the water contains large amounts of suspended solids and contaminants of various kinds, including oil and biological substances. The system is not sensitive to high concentrations and is not pH sensitive. The system is not in need of any pre-treatment systems, but to minimize service work, water comprising larger suspended particles can advantageously pass via some form of separation e.g. a lamella separator.

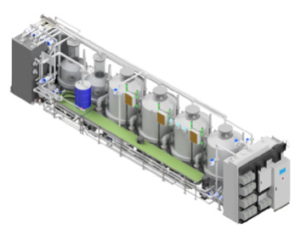

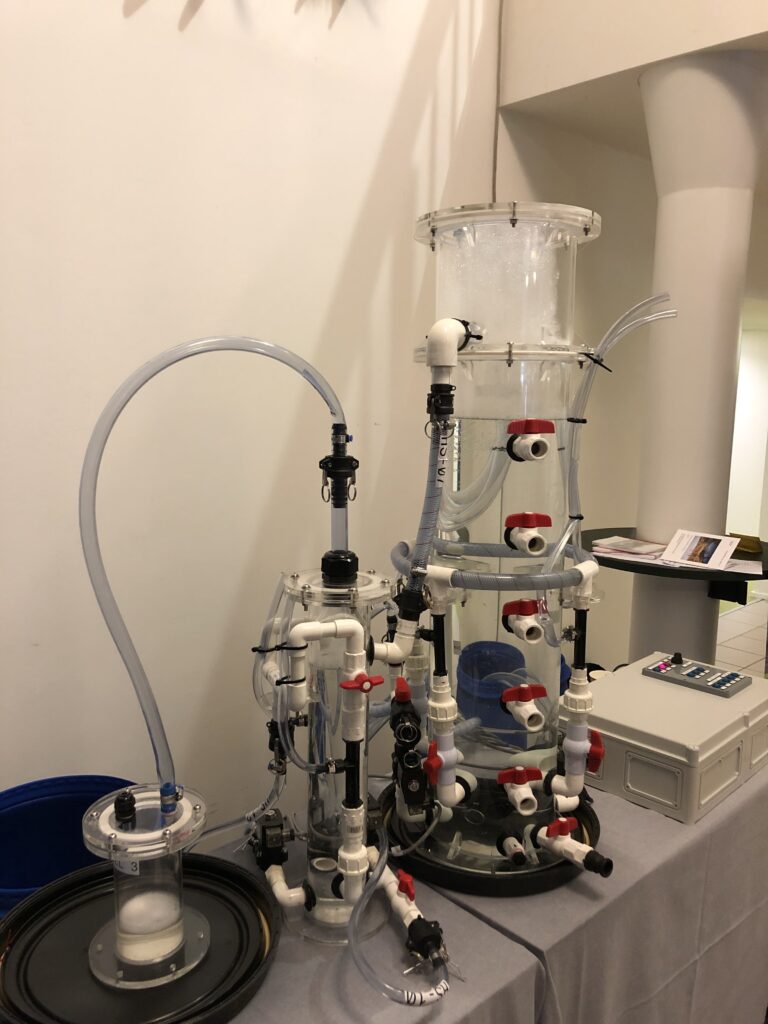

The equipment consists of a number of columns that are connected in series. Figure 1 shows a system with four primary fractionation columns, two secondary columns where one also can perform tertiary fractionation, storage tanks and peripherals. The equipment can normally be accommodated within a 40-foot container, Figure 2.

Figure 1: Layout of a SAFF system.

Figure 2. Photo of a SAFF40 treatment plant.

How does SAFF work?

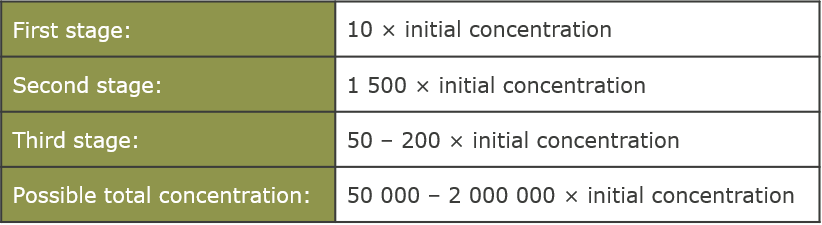

The SAFF system works in three fractionation steps. In the first step, a column is filled with PFAS-contaminated water. Air is injected at the bottom of the column and air bubbles rises through the column. PFAS attach to the bubbles and flow with them to the surface where a foam is formed. PFAS-compounds are thus accumulated at the top of the column. Foam, and some of the water, flow over a weir at the top of the column and is removed. The reason for removing some of the water, and not just the foam, are to effectively remove shorter chain PFAS, which stratifies in the water at the top of the column as they do not have the same foam potential as the longer chains. In this fractionation step the PFAS concentrations increase by about 10-fold.

In the second step, the foam and the water removed is pumped to a second fractionation column, where the same process takes place as in the first column. As concentrations of PFAS are now around 10 times higher, a drier foam is obtained which is removed with vacuum. The vessel where the second fractionation step is performed is equipped with carefully calibrated sensors that control a vacuum pump and its distance to actual process foam levels. The hyperconcentrate generated by this process is led to a collection container where it is stored pending step 3. In this second fractionation step, the concentration is further increased by up to 1,500 times, which means that the total concentration increase is now around 10,000 times initial levels.

In the third fractionation step, which is performed in the same way as step 2, further concentration increases are obtained. The total increase in concentration obtained over the three steps is between 50,000 – 2,000,000 times initial concentrations in the untreated water. The hyperconcentrate waste volumes are therefore this same factor less than the processed feed water volume. Expected amounts of waste depend on the type of water that is treated, but from projects carried out we see that the expected amount of waste for landfill leachate are less than 1 m3 per 40,000 m3 of treated water, and for groundwater about 10 liters per 40,000 m3 of treated water.

The table (below) summarizes the concentration increases at each stage:

Capacity

The capacity of a 40-foot SAFF40, with the possibility of three fractionation steps and internal storage of hyperconcentrate, depends on the type of water to treat and PFAS concentration blend. This is because different PFAS require different cycle times, and the water’s potential to foam determines how much energy the pumps need to provide. From experience a SAFF40 can treat leachate with a capacity of 20-40 m3/h subject to the water’s tendency to foam, while for groundwater it is possible to treat about 40 m3/h with the same equipment and a focus only on PFAS substances with 6 carbon atoms or more. When treatment of shorter chain substances is required, longer batch treatment times may be needed, which results in reduced flow capacity.

SAFF in LIFE SOuRCE

In the LIFE SOuRCE project the SAFF technique will be demonstrated and further optimized for groundwater treatment, as well as coupled with two polishing techniques, AEX and phytoremediation, at two different PFAS contaminated sites; a site in Spain where AFFF products have been used and a landfill in Sweden. The optimization will include testing of a new vessel design, to investigate if higher remediation efficiencies can be obtained with alterations for both short and medium chains. The coupling with polishing techniques will evaluate the efficiency and cost for short chain removal using other techniques, and the economics associated with such a treatment train.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |