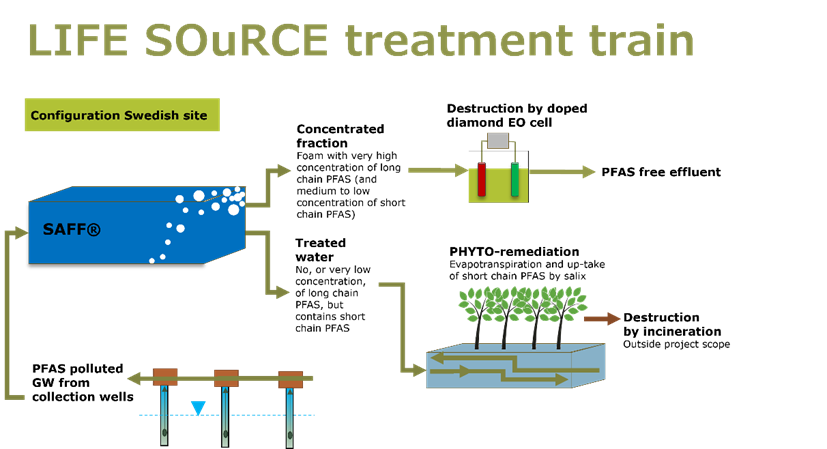

On 27-28 May, LIFE-SOuRCE organised a workshop in Sweden for all partners in the project. During two intensive days, we discussed results and preliminary conclusions from the studies conducted so far. We also arranged a study visit to our Swedish trial site, Hovgården, where our partners responsible for the SAFF, PHYTO and EO technologies showed us around and demonstrated the different steps of the treatment train that is now being tested in Sweden (Figure 1).

Hovgården, owned by Uppsala Vatten, is a waste facility where industrial waste has been deposited since 1971. The groundwater underneath the landfill is contaminated with PFAS, which leaches out from the landfilled waste. In LIFE-SOuRCE, we are now pumping up the contaminated groundwater and treat it with a combination of three different technologies, which we call the LIFE-SOuRCE treatment train, see Figure 1.

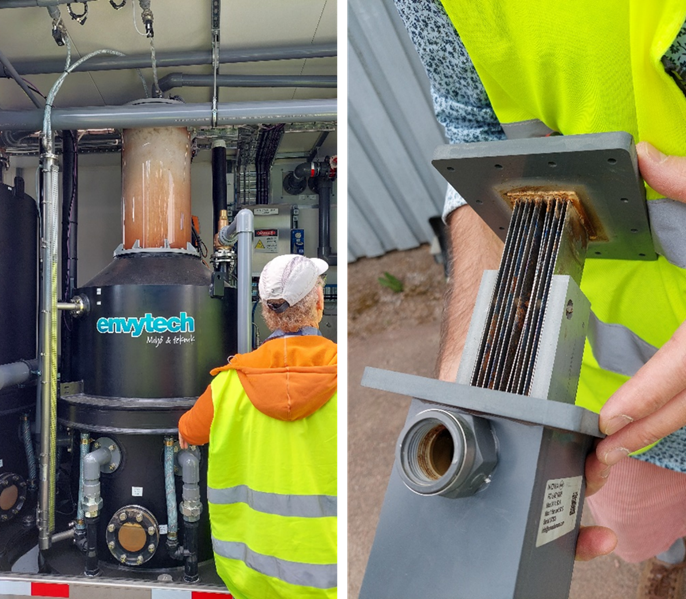

The contaminated groundwater is stored in a tank from which it is fed into the first treatment step which uses the SAFF technique (Figures 2 and 3). SAFF stands for Surface Active Foam Fractionation and is a technique that utilises the physical and chemical tendency of PFAS substances to attach to the stream of air bubbles, which flow from bottom to top through a vessel containing the contaminated water. The bubbles can easily carry the long-chain PFASs, since these molecules like to be at the air-water interface. PFAS with short molecular chains are on the other hand more hydrophilic and are more likely to remain in the water, making it more difficult for the bubbles to catch and carry them to the surface. Therefore, in the SAFF, the water is mainly purified from long PFAS chains, but some of the short-chain PFAS molecules can also be removed. At the top of the SAFF vessel, the air bubbles form a foam with a high concentration of PFAS that can be separated and sent to the next step in our treatment train for PFAS destruction.

The destruction of PFAS in the foam is done using an EO cell where PFAS is destroyed by electrochemical oxidation. The EO cell is made up of several parallel electrodes (see Figure 3) that have a surface of boron-doped diamond. Diamond is a very inert substance with a high electrochemical potential, which is needed to efficiently break down the persistent PFAS molecules.

With the SAFF, we can purify the water from long-chain PFAS and reach purification rates of over 99%, but the technology is not yet as effective at purifying the short PFAS substances. Therefore, we are testing if the SAFF treated water could be further polished with a phytoremediation technique, we call PHYTO. In this step a part of the SAFF effluent is thus led to our text PHYTO bed with Salix Wilhelm.

Salix (willow) is an energy crop that has a high evapotranspiration rate, which means that this plant can take up large amounts of water as it grows. Salix is already used today to reduce leachate emissions from landfills. In our pilot studies, we have shown that Salix Wilhelm (and other plants) can also take up short-chain PFAS compounds into their aboveground biomass (mainly in leaves and branches).

In the PHYTO test bed, (Figure 4), our goal is to have zero, or very low, discharge of water. Instead, the full volume of water that is pumped into the test bed will be evapotranspired by the plants and simultaneously the short chain PFAS will be enriched in the biomass, which can then be harvested and burned to destroy the PFAS.

Low concentrations of long-chain PFAS that may remain in the water out of the SAFF may also stuck (be adsorbed) to the solid material in which the Salix Wilhelm is grown (the substrate) and to the root system of the plants. The cultivation substrate consists of a mixture of leca balls, peat and biochar. The cultivation bed has a sealed bottom so that there is no leakage to the underlying soil and the water in the bed is recirculated to improve the degree of purification.

For this last step in the process to be both environmentally and economically beneficial, it is a prerequisite that the PFAS are fully destroyed during incineration and that the energy generated can be utilised. Exploring whether this is possible, or not, lies outside the scope of the LIFE-SOuRCE project, however research is already ongoing elsewhere, for example through SGI’s government assignment on thermal treatment of PFAS, which is being carried out together with Örebro University.